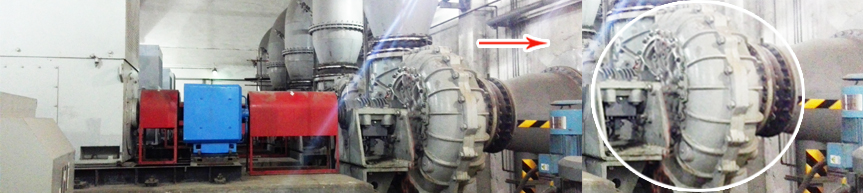

Excellence technicians went to visit the client and check the EVR-250T sump pump running status in June, 2014, which is one month after installation. No abnormal data are found in the pump operating temperature and vibration tests. They give some suggestions to clients according to site working condition.

The picture below is Excellence engineer visiting the working site: